In the dynamic world of fashion and apparel, sourcing decisions are pivotal. Brands constantly seek the optimal balance between cost, quality, and speed. China has long been the epicenter of clothing manufacturing, but rising costs and global shifts have prompted businesses to explore alternatives.

This article delves deep into the clothing manufacturing costs in China compared to other prominent countries, providing insights to aid in strategic sourcing decisions.

China’s Dominance in Clothing Manufacturing

Historical Context

China’s ascent as the “world’s factory” is rooted in its vast labor force, infrastructural investments, and favorable government policies. Over the past few decades, it has established a robust supply chain ecosystem, making it a go-to destination for apparel production.

Cost Structure

- İşçilik Maliyetleri

While still competitive, China’s labor costs have been on the rise. As of recent data, the average manufacturing labor cost is approximately $6.50 per hour.

- Altyapı

China boasts state-of-the-art infrastructure, ensuring efficient production and logistics.

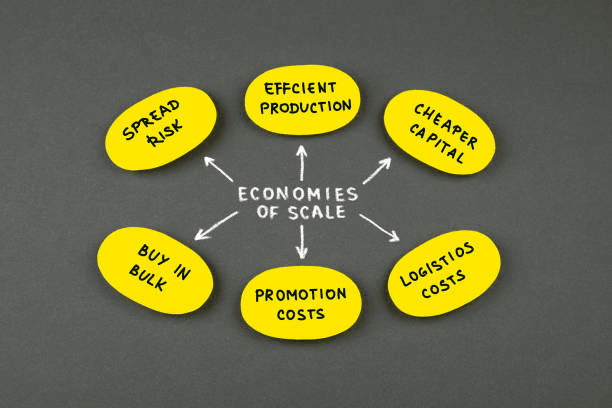

- Ölçek Ekonomileri

Large-scale operations allow for cost efficiencies, especially for bulk orders.

Avantajları

- Comprehensive Supply Chain

From raw materials to finished goods, China’s integrated supply chain reduces lead times.

- Technological Advancements

The Adoption of automation and advanced manufacturing techniques enhances productivity.

Zorluklar

- Rising Costs

Increasing wages and operational costs are narrowing profit margins.

- Trade Tensions

Tariffs and geopolitical issues, especially with the U.S., have introduced uncertainties.

Exploring Alternative Manufacturing Hubs

Vietnam

Vietnam offers lower labor costs, averaging around $2.99 per hour, making it an attractive alternative.

- Production Capabilities

While not as expansive as China, Vietnam’s manufacturing sector is growing rapidly, with significant investments in technology and infrastructure.

- Trade Agreements

Vietnam’s participation in multiple free trade agreements provides favorable export conditions.

- Skilled Workforce

A young and increasingly skilled labor force supports diverse manufacturing needs.

- Infrastructure Gaps

While improving, certain areas still lack the infrastructural maturity seen in China.

- Supply Chain Limitations

Dependence on imported raw materials can affect lead times and costs.

Hindistan

- İşçilik Maliyetleri

India’s labor costs are competitive, especially in the textile sector.

- Production Capabilities

India has a vast textile industry, with strengths in cotton and handloom products.

- Diverse Product Range

From traditional garments to modern apparel, India offers a wide array of products.

- İngilizce Yeterliliği

Facilitates smoother communication with Western clients.

- Altyapı Sorunları

Logistical challenges and infrastructural bottlenecks can impact efficiency.

- Düzenleyici Engeller

Complex bureaucratic processes may pose challenges for foreign businesses.

Bangladeş

- İşçilik Maliyetleri

Among the lowest globally, making it a hotspot for cost-effective manufacturing.

- Production Capabilities

Specializes in the mass production of basic apparel items.

- Government Incentives

Tax breaks and favorable policies support the textile sector.

- Export Benefits

Duty-free access to major markets like the EU enhances competitiveness.

- Safety Concerns

Past incidents have raised questions about factory safety standards.

- Infrastructure Limitations

Port congestion and transportation issues can delay shipments.

Comparative Analysis

| Country | Labor Cost (per hour) | Altyapı | Supply Chain | Trade Agreements | Safety Standards |

| Çin | $6.50 | Advanced | Comprehensive | Moderate | Yüksek |

| Vietnam | $2.99 | Developing | Growing | Extensive | Improving |

| Hindistan | $1.80 | Developing | Diverse | Moderate | Değişken |

| Bangladeş | $1.00 | Sınırlı | Specialized | Favorable | Concerns Exist |

Factors Influencing Manufacturing Costs

İşçilik Maliyetleri

Labor remains a significant component of manufacturing expenses. Countries with lower wages naturally offer cost advantages, but it’s essential to balance this with productivity and quality.

Altyapı

Efficient transportation, reliable utilities, and advanced facilities reduce operational hiccups and ensure timely deliveries.

Supply Chain Integration

Proximity to raw materials and ancillary industries can significantly cut down costs and lead times.

Regulatory Environment

Stable political climates, transparent regulations, and supportive government policies create conducive environments for manufacturing.

Çözüm

Navigating the complex landscape of global clothing manufacturing requires a nuanced understanding of various factors. While China continues to be a dominant player, countries like Vietnam, India, and Bangladesh offer compelling alternatives, each with its unique advantages and challenges. Businesses must weigh these factors carefully, aligning them with their strategic goals, to make informed sourcing decisions.

SSS

Which country is the cheapest to manufacture clothes?

- Ölçek Ekonomileri

China’s expansive manufacturing infrastructure supports large-scale production, which significantly lowers the cost per unit. This ability to produce in bulk helps drive down overall product prices.

- Material Costs

China often benefits from easier access to raw materials, with many sourced locally. This local availability can lead to lower material costs compared to countries that rely heavily on imports.

How much import duty is on clothes from China?

BCD rate for clothes: 20%

-300x198.png)