As one of the world’s largest manufacturing hubs, China offers an expansive network of suppliers, a wide range of production options, and highly competitive pricing.

However, to ensure a smooth and efficient manufacturing process, it’s essential to have a deep understanding of key aspects such as procurement and compliance.

If you’re considering abastecimiento de productos or establishing manufacturing in China, this guide will walk you through each step, providing you with the insights needed to effectively navigate the journey of manufacturing in China. Let’s dive in and explore the process together!

Do Research to Identify Your Products

Define Your Product

Clearly outline what you want to produce. Consider:

- Materials Needed

Specify the types of materials required for your product. This could include plastics, metals, textiles, or other specialized materials. Be clear about the grade, quality, and any specific properties that the materials should have to meet your product’s requirements.

- Product Design and Features

Provide a detailed description of the product design, including the shape, style, and any unique features it should have. This might involve functional elements (such as buttons, screens, or special compartments), as well as aesthetic features (like texture, finish, or branding).

- Dimensions, Weight, and Color Options

Clearly state the desired dimensions (length, width, height) and weight of the product. Additionally, specify the range of color options you want to offer, as well as any variations in design or size that might be needed for different models or markets.

Consider Your Budget

Understanding your cost structure and determining how much you’re willing to invest is crucial. A clear budget will allow you to evaluate the types of manufacturers you can afford, taking into account their pricing, quality, and production capacity.

Assess Your Production Volume

If you’re planning to source products from China for the first time, your initial order may not be large. Therefore, it’s important to choose manufacturers who are open to small-batch production.

Research Competitors in The Same Industry

After spending time researching products that have both succeeded and failed, the next step is to identify a few key competitors or role models whose strategies you’d like to emulate to some extent. Here are some ways that you can choose:

Use Online Platforms

- Analyze Websites

Look at their design, user experience, product offerings, pricing strategies, and any promotional content. This will help you understand how they present themselves and what sets them apart in the market.

- Analyze the industry traffic trend

Tools like Google Trends, SEMrush, or Ahrefs can give you insights into how much traffic competitors are getting, where their traffic is coming from, and what kind of keywords they are ranking for.

This can provide valuable information about the overall demand for the products or services in your niche.

- Gather competitor keyword

By using SEO tools, you can identify the specific keywords your competitors are targeting and rank for. Additionally, look for gaps in their content strategy or areas where you can outperform them with better content or SEO tactics.

Request Samples

It is essential to always request product samples before committing to a large order. By doing so, you can:

- Evaluate the Quality

Reviewing a sample allows you to physically inspect the product’s quality, ensuring it meets the standards and expectations you have for your business or customers.

- Confirm Product Specifications

Requesting a sample helps verify that the product matches the specific details and requirements outlined in your order, such as dimensions, materials, design, or functionality.

- Test the Supplier’s Reliability

Receiving a sample also allows you to assess the supplier’s ability to adhere to deadlines and deliver products promptly, helping you gauge their reliability for future orders.

Check Certifications

Ensure that the manufacturer has the necessary industry certifications (e.g., ISO, CE, UL, etc.). This will help guarantee that the product meets your quality standards and complies with international regulations.

Assess and Negotiate Pricing

Capacidad de producción

It’s essential to assess whether the manufacturer can meet your required production volume and delivery timeline. Ensure they can scale up or adjust to your needs without compromising quality or efficiency.

Control de calidad

Understand the steps the manufacturer takes to maintain and ensure consistent product quality. From raw material selection to final inspection, inquire about their control de calidad processes, certifications, and standards they adhere to during production.

Unit Price

Do negotiate pricing to make sure the unit price is competitive and aligns with your budget expectations. A good balance between cost and quality will contribute to the long-term success of your partnership.

Condiciones de pago

Typically, payment terms consist of an upfront deposit, usually around 30%, with the remaining 70% due after the order is shipped. However, it’s important to discuss the specific terms and payment structure that work best for both parties, ensuring financial stability throughout the process.

Sign the Agreement and Perform Quality Inspections

Clear Agreement

It’s essential to establish a clear and comprehensive agreement between both parties to ensure mutual understanding and alignment. This agreement should explicitly outline key aspects such as the production timelines, payment terms, and specific quality expectations.

Legal Protection

To safeguard your interests and avoid any future conflicts, it’s crucial to have a legally binding contract in place. A solid contract can protect in case of breaches or misunderstandings, providing a legal framework to resolve any issues.

Factory Inspections

On-site factory inspections allow you to assess the production environment, verify the manufacturer’s capabilities, and ensure they adhere to safety standards, production processes, and quality control measures. This step helps identify any potential issues early on and ensures the factory can meet your expectations.

Arrange Shipping and Logistics

Shipping Method

Choose between air freight, which is faster but more expensive, and sea freight, which is cheaper but slower.

Customs Clearance

Ensure compliance with customs regulations when importing goods from China, including necessary documentation and payment of import duties and taxes.

Incoterms

Clarify who is responsible for shipping costs and duties, such as with FOB (Free on Board) or CIF (Cost, Insurance, and Freight), to avoid confusion over costs and responsibilities.

Build a Long-Term Relationship

Maintain Communication

Regularly check in with your manufacturer to ensure everything runs smoothly.

Visit the Factory

If possible, visit your manufacturer in person to build a stronger relationship and resolve any potential issues.

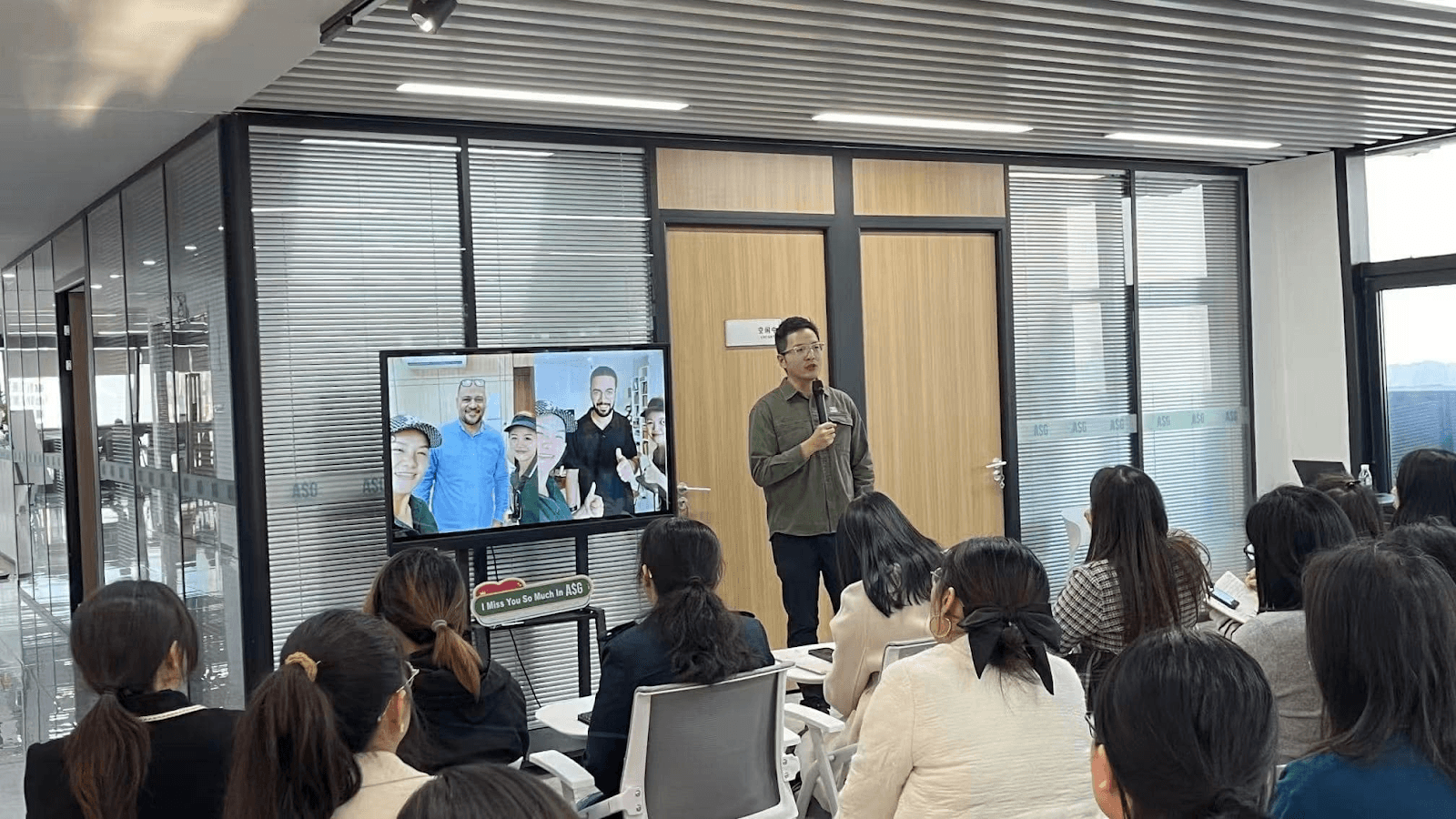

ASG Offers Help

ASG is a leading sourcing company located in Guangzhou, Guangdong Province. We are your one-stop solution for turning your China sourcing vision into reality. From start to finish, we connect you with trusted manufacturers, ensuring your ideas come to life with precision and quality.

With years of industry experience and a deep understanding of the global market, we take pride in our ability to meet the diverse needs of clients across various sectors.

Conclusión

Manufacturing a product in China can be a highly rewarding process, offering competitive pricing, high-quality production, and a range of customization options.

By following these steps and thoroughly vetting your potential suppliers, you can ensure a smooth and successful manufacturing experience. Remember that clear communication, quality control, and legal protection are key elements to building a solid relationship with your manufacturer.

-300x198.png)